IVEA develops innovative technologies (3): From two sentences of specifications to a patent...

IVEA develops innovative technologies (3): From two sentences of specifications to a patent...

Posted on October 14, 2019

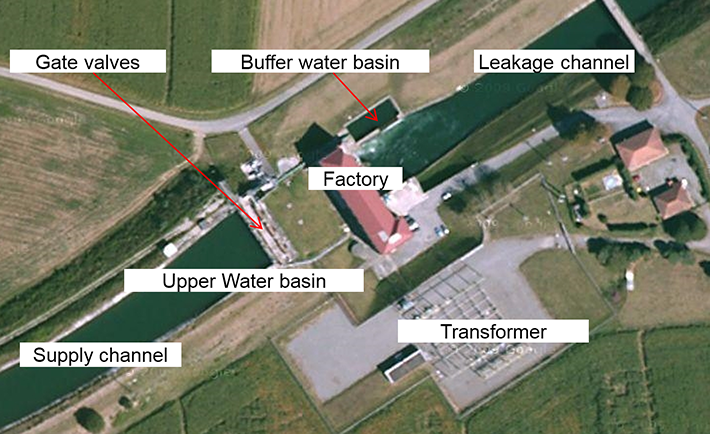

As part of the refurbishment of the 3 head valves, fixed parts and control system of the CAMON EDF power plant in Labarthe-Rivière (31), IVEA was responsible for the remotorization of the structure. A service that allowed him to design - and ultimately patent - a valve control system to control the gravitational lowering speed of a water retention structure valve....

In its "design provisions", the specifications succinctly stated: "For a valve closing by gravity, a suitable and easily accessible device allows the speed of descent to be limited. Special braking, if necessary, at the end of the stroke prevents the moving part from suddenly hitting the threshold." These two short sentences tickled the creativity and mobilized the expertise of IVEA, responsible for re-motorizing the venerable structure dating from... 1933!

The principle of a power plant

The principle of a power plant

The old braking system

The old braking system

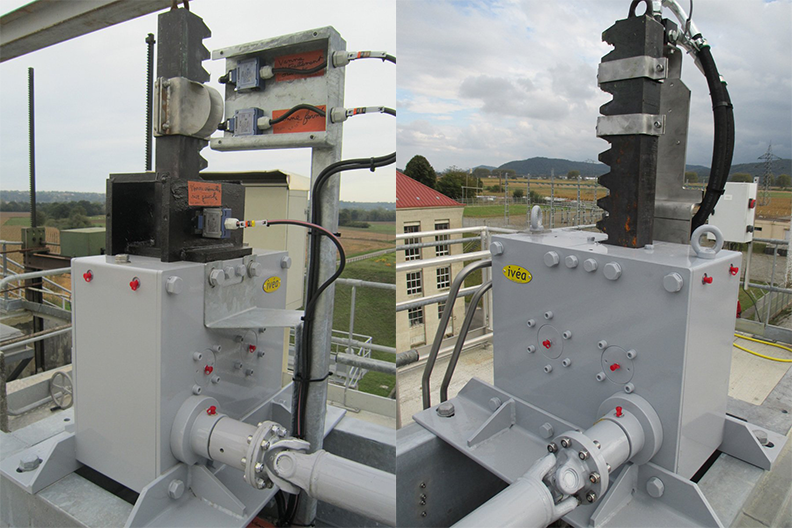

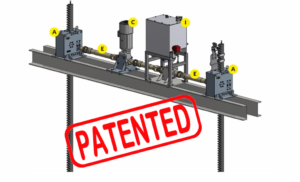

For this reengineering, IVEA designed, built and installed on site a set of motorized coupled jacks for gravity closure (force: 420 kN / stroke 5000 mm). A high-performance system, which makes it possible to raise the valve, keep it in the open position and automatically ensure its gravity closure as soon as the power supply is cut off.

A:Jack box with rack C:Gear motor E:Transmission shaft D:Braking module

A:Jack box with rack C:Gear motor E:Transmission shaft D:Braking module

But above all, as part of this service, its in-depth thinking has enabled IVEA to design, test and validate an autonomous and innovative device to regulate the valve's lowering speed and cushion the end of the stroke! A major technological advance which, guaranteeing zero maintenance and zero wear and tear, was well worth the filing of a patent...