IVEA develops innovative technologies (2): Patent N° 1552212 : Gravity valve closing brake !

IVEA develops innovative technologies (2): Patent N° 1552212 : Gravity valve closing brake !

Posted on October 14, 2019

A gravity shut-off valve closes under its own weight as soon as the power supply is interrupted. A new device patented by IVEA makes it possible to regulate the lowering speed of the valve and protect it from any impact with the structure's threshold...

Last May in this blog, we inaugurated a series of articles under the title "IVEA develops innovative technologies". We continue this series by illustrating it with two successive articles on:

- a context: the gravity closure of hydroelectric valves (below)

- our solution: a patented system !

In the field of water retention structures, valves are used to selectively open and close a water flow channel via an actuation system. They are used on dams to close a channel connecting the water retention to a turbine: the rotation of the latter stops as soon as its water supply is interrupted.

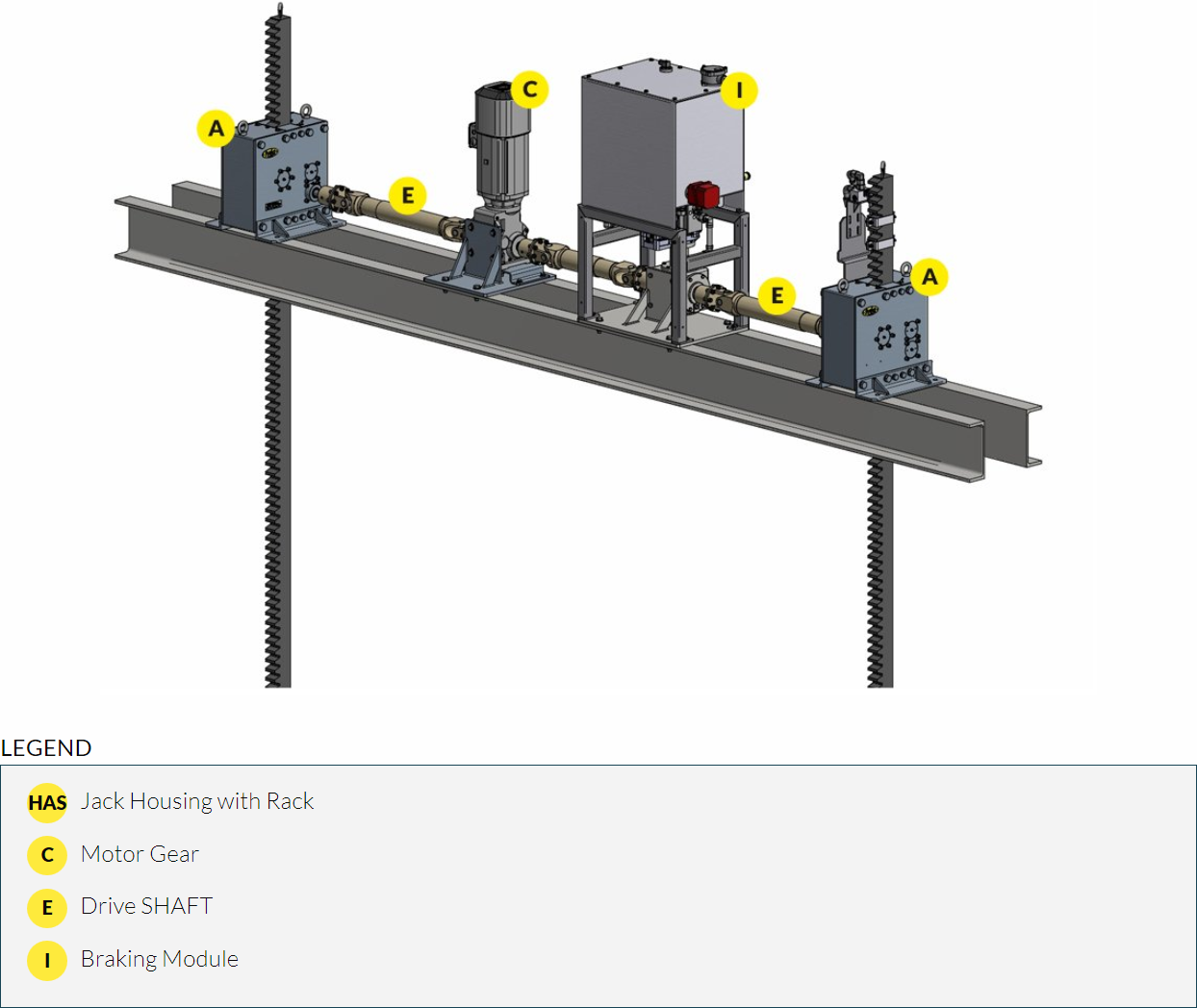

For a gravity shut-off valve, a dedicated and accessible system is essential to regulate the valve's lowering speed under the effect of its own weight: following a general power failure or a voluntary interruption to ensure an inspection or maintenance operation of the turbine, a special braking at the end of the stroke must prevent the sudden impact of the moving part on the threshold.

If such a device is already known and in service, notably at the CAMON hydroelectric power plant in Haute-Garonne (below), it is still more than three-quarters of a century old! Its design, its electromechanical technique, its size, its capacities..... were heavily influenced by their age!

The EDF Camon power plant

The EDF Camon power plant Machinery before remotorization work

Machinery before remotorization work

As a specialist in the motorization of structures on waterways, IVEA developed on this occasion a new solution and filed a patent related to the gravity closure of turbine isolation valves by jacks (Patent No. 1552212).