Autonomous jacks: 5 by-pass gates motorized by IVEA on the side channel of the Garonne River

Autonomous jacks: 5 by-pass gates motorized by IVEA on the side channel of the Garonne River

Posted on January 20, 2020

On the Canal Latéral à la Garonne, the water slope of MONTECH (82) is no longer in service, but a chain of 5 locks allows river navigation to free itself from successive gradients. As part of the automation work carried out by VNF Direction Territoriale Sud-Ouest, IVEA has motorised the diversion valves using autonomous actuators. A return to the very source of its history...

A by-pass by manual operation with rack jacks .

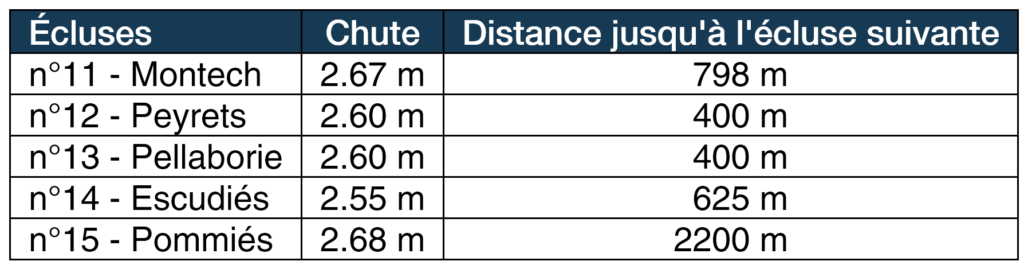

Locks 11 to 15 at MONTECH (82) divide a 2,161 m stretch into 4 bays, with an annual traffic of around 1,500 vessels. The work undertaken by VNF Sud-Ouest consisted in automating these locks and their diversion in continuity with the upstream and downstream sectors of the canal. While almost all of the locks on the canal are now automatic, locks 11 to 15 were still operated by operators from manual consoles on the medians.

However, the part we are interested in concerns the supply of water to the tailbay of each of the five locks, obtained by means of a diversion. Until then, the flow rate was controlled by a manually operated rack-jack valve, a restrictive and obsolete system, given the need to regulate diversion bay levels. This is where IVEA was able to bring its expertise to bear once again. And operate a historical return to its origins...

... to an automated system of autonomous cylinders with position sensors.

Indeed, as a pioneer in the field of motorisation of diverter valves, it was for a site of this nature that IVEA received its first order and started its great industrial adventure in 2002! In other words, 17 years later, a lot of water has flowed on the waterways in France and elsewhere and IVEA has consequently enriched its expertise. Not only in independent actuatorsbut in all types of motion and power transmission solutions for multiple sectors of activity!

For Montech's control valves, IVEA has designed and manufactured 12 autonomous cylinders (80 kN force, 1300 mm stroke): sophisticated assemblies in which each double-acting cylinder supports its own hydraulic power unit. The "plus" of this technology was provided by the position sensors integrated into the cylinders, which are essential for automating the structure with the aim of regulating the flow rate in each forebay.

This sensor allows to intervene accordingly on the position of the valve. The operator is thus assured of easy regulation and maintenance of the water level for navigation in each forebay, by rebalancing all the hydraulic flows that disturb it! The result is a modern, efficient and reliable automated system, supplemented for all intents and purposes by a hand pump offering a manual back-up device.

IVEA's mastery of such systems has been and continues to be demonstrated through its specific references in self-contained cylinders (for supply, diversion, discharge, regulation, gate and vantelle, fish ladders, flap gates...) which since 2002, are therefore enriched over time, as the water goes by...